Over 20 years of testing and research experience

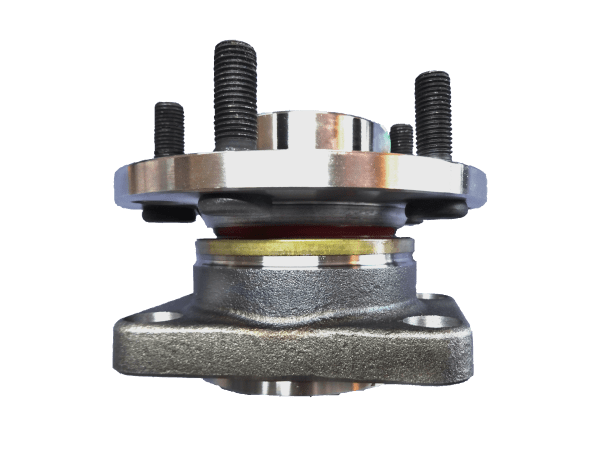

Wheel bearings testing machines

Wheel bearings are key determiners of energy efficiency and reliability in the mobility sector regardless of a vehicle’s drive type. SincoTec offers a broad spectrum of bearing test systems to determine the lifecycle and fatigue strength of components as well as to conduct function and frictional torque testing.

Our product offering for wheel bearing and frictional torque testing in the personal and commercial vehicle sectors

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Wheel bearing testing machines

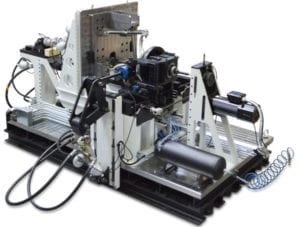

4 axial wheel bearing test system

- for block programs

- for operational load simulations

3 axial wheel bearing test systems

- for block programs

- for operational load simulations

2 axial test systems

- Wheel bearing rotating bending test rig to conduct lifecycle/impermeability experiments with dirty water/corrosive liquids per PV 2010

- Variable temperature environments are possible

- Special variants with oscillating weights and active braking systems

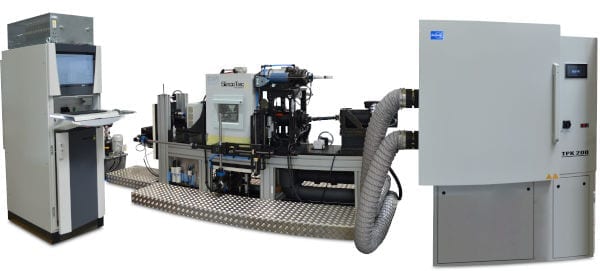

Frictional torque measurement test system

A frictional torque measurement testing machine offers the opportunity to determine the frictional torque on wheel bearings/wheel bearing units under the influence of vertical and lateral forces and the therefrom resulting camber moments at freely selectable environmental temperatures.

Biaxial test system for block programs per PV 8607

Single axle test system

Did you know that ...

… with our newly developed frictional torque test measurement testing machine we can help you increase the range of e-vehicles?

Our test rigs determine the wheel bearing friction according to WLTC (PV8607).

Our product offering for bearings in the railway sector

2 axial lifecycle testing

Two different rigs are combined for railway bearing testing:

- Heavy Duty for block programs up to 3,000 rpm

- High Speed for block programs up to 4,000 rpm