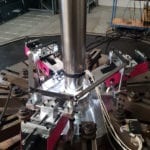

Our component-specific testing machines

Testing machines for wheels, wheel flanges, and wheelset shafts

Vehicle wheels are subjected to complex stresses. External rotating bending loads exert particularly heavy stress on the connecting areas of the wheel such as wheel flanges and flange bearings and their screw connections.

The axles and wheels of railed vehicles are also subject to complex loads. The wheel disc area or wheelset axle is particularly stressed by rotating bending loads. All of the components of the wheelset, such as the wheelset and three-center curve of the shaft, are also subject to rotating bending loads.

These loads can be exactly replicated through unbalanced mass rotating bending test rigs in the laboratory.

Quick navigation:

POWER ROTATING bending

for strength testing of car, motorcycle, and bicycle wheels

for strength testing on wheel flanges, axle pins, and screw connections

Rotating bending

- 4 rig sizes at rated loads between 2,000 Nm and 12,000 Nm

- Rotation bending loads

- All the advantages of resonance testing technology

POWER ROTATING bending truck/railway

for strength testing of railway wheels and wheelset shafts

Rotating bending

- Testing according to norms DIN EN 13260, 13261 und 13262

- 3 test rig sizes between 80,000 Nm and 350,000 Nm

- Rotational bending loads

- Load realistic control on maximal elongation amplitude

- All the advantages of resonance test technology

Crack propagation examination with high speed cameras

Extend your strength testing of truck wheels and wheelset axles with crack propagation analysis.