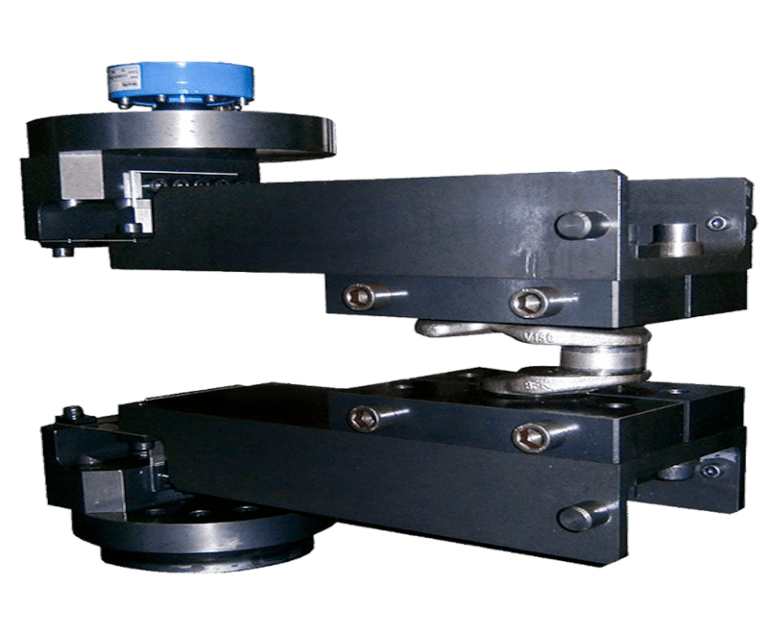

Design of test fixtures

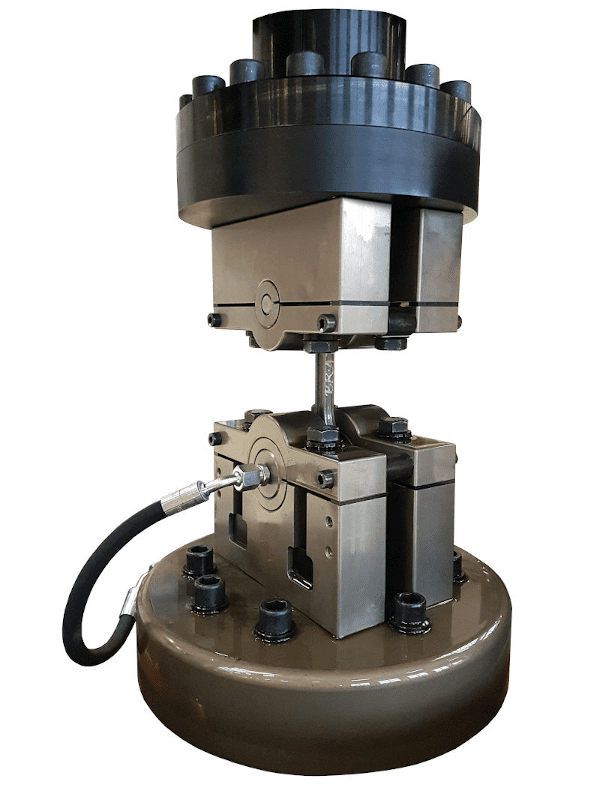

Test fixtures ensure that our universal test rigs apply highly realistic loads to your sample. Part of the test process always includes developing different types of clamps for new test scenarios.

Our fixtures need to endure fatigue and be particularly wear-resistant while also having a precise geometry and being carefully constructed such that no unwanted loads are applied to the component.

At SincoTec we have been developing test fixtures that deliver the exact stresses and forces that you want to test since 1991. Our wealth of knowledge and experience and toolkit of proven standard and custom test fixtures ensure that we develop the best product for your requirements.

Services offered

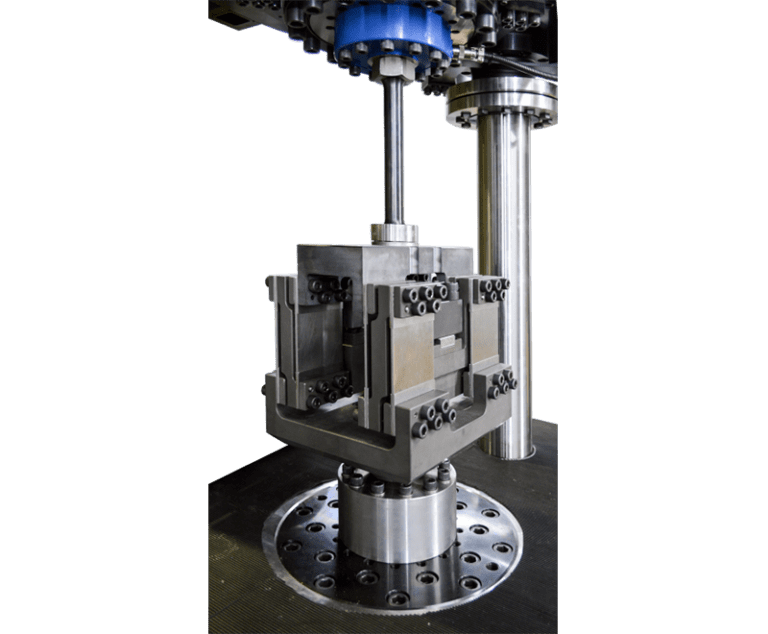

What we develop:

- For almost every component/component group:

- Standard testing devices

- Component specific testing devices

- For almost all loads types up to ±2 MN or ±400,000 Nm:

- Axial loads

- Multiaxial loads

- Torsional loads, bending and rotating bending loads

- Combined loads

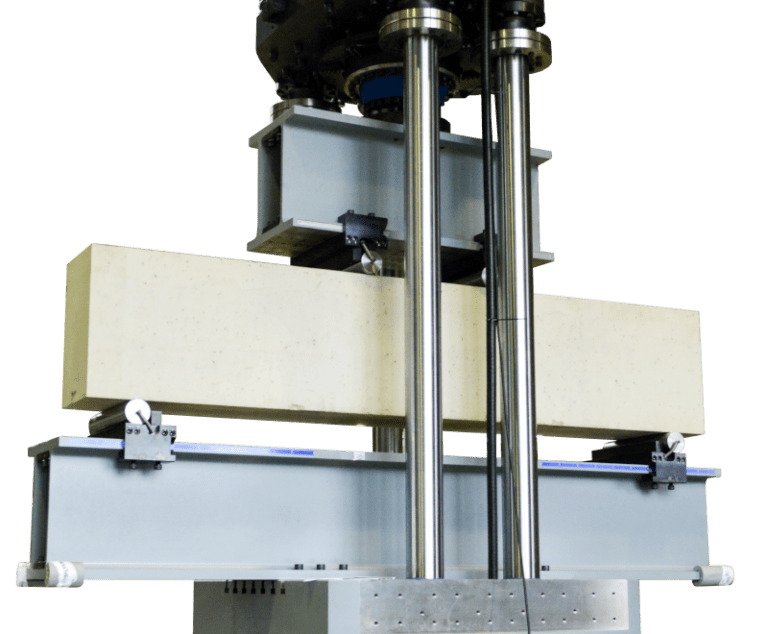

- Combination with environmental simulations

Why SincoTec:

- Fixtures constructed to prevent unwanted transverse forces

- High levels of fatigue endurance

- Precise load initiation

- Accurate representation of the operation of the part in situ

Do your components need to be tested?

When it comes to testing your products, components or component groups on their load capacity, lifetime and reliability that‘s where we have the right solution. Please shortly tell us about your problem and we will reach out to you as soon as possible!