More Accurate, Faster, Safer - TestPilot 2.0

Newly Developed Controller Hardware for Forced Excitation Test Systems

TestPilot 2.0

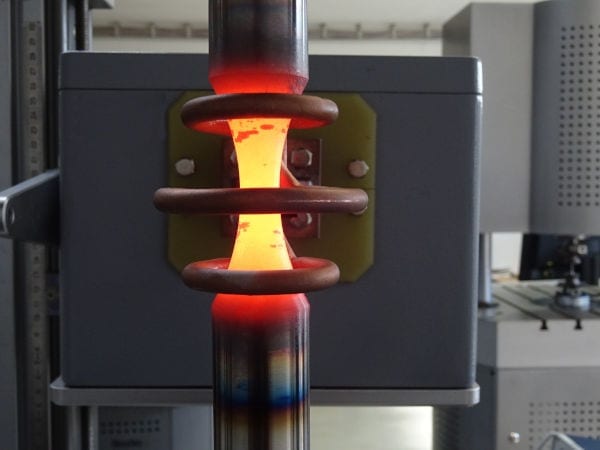

Our in-house developed TestPilot hardware has undergone a significant upgrade. The enhancements include an increased measurement and control rate of 50 kHz per channel and improved measurement accuracy to 24 bits. Utilizing a high-performance, real-time capable MultiCore CPU, TestPilot 2.0 is equipped to handle increasingly complex testing tasks.

The controller is versatile, available either as a standalone unit or for cabinet installation in two different sizes. The first variant is a cost-effective, up to two-axis version suitable for simpler test setups. The second is an up to eight-axis version designed for more demanding multi-axis applications. Both versions have enhanced digital inputs and outputs, now featuring 32 of each, with some capable of functioning as counter inputs (A or AB).

Safety has also been elevated in the new model. By incorporating special positively driven relays with feedback to control media release, the system achieves Performance Level “d” (ISO 13849), ensuring higher safety standards.

TestPilot 2.0 continues to be operated via our well-established CoPilot PC software, which supports seamless integration and operation with all generations of TestPilot controllers.

Key Features of TestPilot 2.0:

Measuring and control rate of 50 kHz per channel

Measurement accuracy of 24 bits

Available as a standalone device or for cabinet installation in two configurations:

Up to two-axis for simpler setups

Up to eight-axis for complex multi-axis applications

32 enhanced digital inputs and outputs, some usable as counter inputs

Enhanced safety with Performance Level “d” certification

Operated using the trusted CoPilot software for effortless compatibility with previous controller generations

TestPilot 2.0

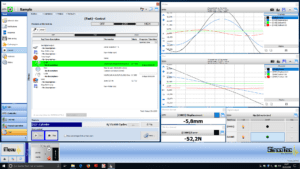

SincoTec CoPilot user interface with running test

How can we help you?

When it comes to testing your products, components or assemblies for their load capacity, service life and reliability, we have the right solution. Please briefly describe your problem, we will be happy to get back to you in a timely manner!