Test rig for fatigue testing

POWER SWING MOT

Your all-round talent for component testing

1 rig – over 1,000 uses

Highlights

- Universally appplicable

- Automatic crack detection

- Short testing times

- Energy efficient

- Worlds largest test stroke

- Perfect for asymmetric test fixtures because of the lack of effects from transverse forces

Examples

- Rotor

- Connecting rod

- Transformer plate

- Motor block

- Prosthetic adapter

POWER SWING MOT's capabilities

The POWER SWING MOT is our all-purpose tool among the SincoTec test systems to generate static and dynamic testing of components and materials especially in the infinite and finite domains of fatigue life. The test rig can be used for almost every component and can generate all load types.

Thanks to the resonance principle the POWER SWING MOT is extremely energy efficient, fast, and highly accurate.

Want to see the POWER SWING MOT in action? Make an appointment in our test laboratory and come check it out.

Your all-rounder for dynamic fatigue strength testing!

Tension-Compression

Bending

Torsion

Internal Pressure

Technical Highlights

Your Advantages

Technical Highlights

- Resistance to clearance and attenuation

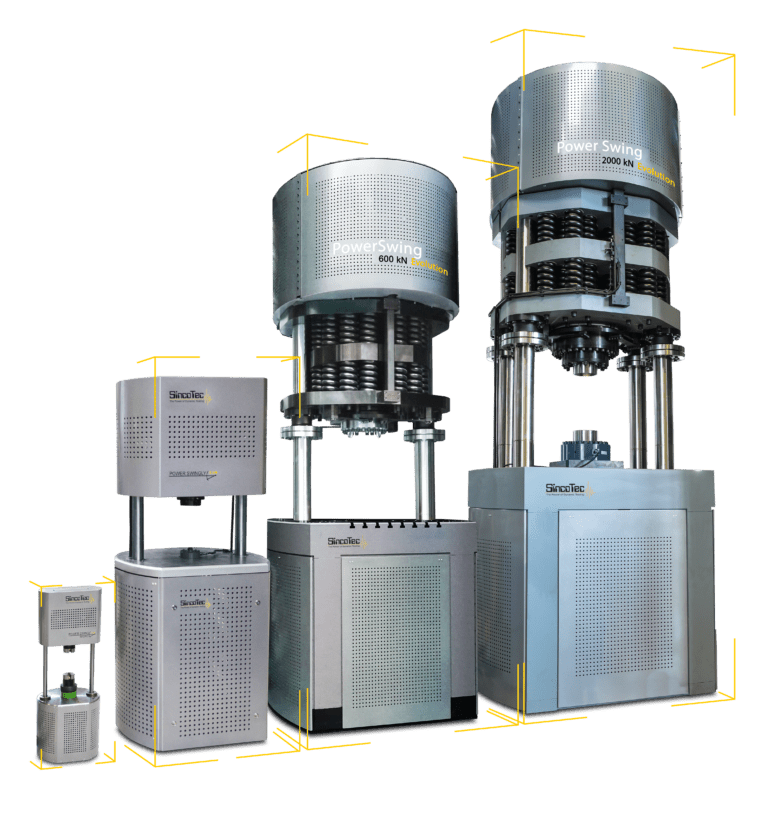

- Generates loads from very small (1 kN) to very large (2,000 kN)

- High frequencies up to 120 Hz

- High stroke up to 12 mm

- Variable average loads

- Integrated, low-wear, guidance system

- Additional guidance system to apply dynamic loads

- Six different product variations

Your Advantages

- Short testing times

- Low operating costs thanks to the resonance principle and low infrastructure requirements

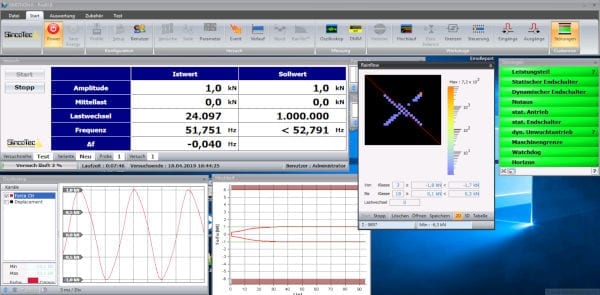

- Highly precise thanks to SincoTec’s control system EXCITING MOT (optimizing control programs)

- Automatic crack detection thanks to the resonance principle

- Lower maintenance costs due to low wear components

- High occupational safety

- Easy usage with SincoTec’s test software EMOTION

- Ergonomic usage

- Easy test sample changes

- Proven test technology with over 2,000 resonance test systems in use around the globe

Typical Components:

- Connecting rods

- Driveshafts

- Screws

- Bolts

- Bicycle components

- Chain tightener

- Hinges

- Springs

- Adhesive bonded joint

- Motor blocks

Industries:

- Automotive

- E-Mobility

- Commercial vehicles

- Component suppliers

- Railways

- Construction

- Medical technology

- Shipping

- Green energy

- Oil & natural gas

- Machinery & tools

- Bikes and motorcycles

- Materials

- Aerospace and space flight

EMOTION Software

Software Recommendations:

- Block programs

- Static tests

Accessories:

- Standard test fixtures

- Customized test fixtures

- Protective casings

- Temperature control

- Environmental simulations

- Measurement instrumentation

For every usage, the optimal variant for fatigue testing

|  |  | |

|---|---|---|---|

MOT | POWER SWINGly micro | POWER SWINGly | POWER SWING evolution |

Nominal Load [kN] | 1 | 5 – 20 | 50 – 2.000 |

Static Load +/- [kN] | 1 | 5 – 20 | 50 – 2.000 |

Maximum Dynamic Force Amplitude +/- [kN] | 0,5 | 2,5 – 10 | 25 – 1.000 |

Maximum Dynamic Stoke [mm] 1 | 4 | 10 | 6 – 10 |

Frequency Range [Hz] 2 | max. 95 | 30 – 110 | 30 – 120 |

Number of Test Rig Siyes | 1 | 3 | 10 |

Uses | High precision at low force levels; transportable | Applications from small to passenger vehicles; large displacements | Especially for heavy and large components (commercial vehicles, shipping) |

1 Others available on request

2 Depending on test sample strength and machine size

|  |  | |

|---|---|---|---|

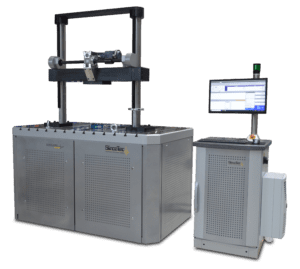

MOT | POWER SWING compact table | POWER SWING big table | POWER SWING low frequency |

Nominal load [kN] | 20 – 100 | 20 – 100 | 20 – 100 |

Static load +/- [kN] | 20 – 100 | 20 – 100 | 20 – 100 |

Maximum Dynamic Force Amplitudes+/- [kN] | 10 – 50 | 10 – 50 | 10 – 50 |

Maximum Dynamic Stroke [mm] 1 | 12 | 12 | 12 |

Frequency Range [Hz] 2 | 30 – 115 | 30 – 115 | 5 – 10 |

Test Rig Sizes | 3 | 3 | 3 |

Features | For excentric test fixtures | No size limits for test samples: for test fixtures (long lever arms, especially for test fixtures)

| Besonders für niedrige Frequenzen

|

1 Others available on request

2 Depending on test sample strength and machine size