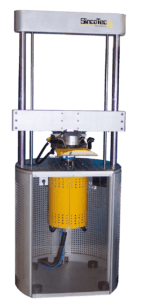

Servopneumatic universal testing machine POWER AIR

Your universal test system for low load range component testing

Highlights

- Universally applicable test systems

- Variable height test sample area

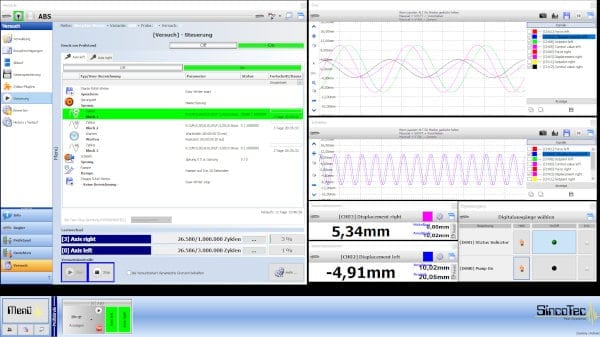

- Determination of force and displacement characteristic curves

Uses

- Testing of elastomer elements

- Testing of pedelec components

- Vibration testing up to 50 Hz

- Material testing for medical technology

POWER AIR's capabilities

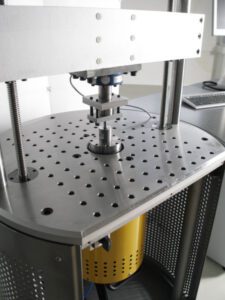

The universal, servo pneumatic testing system POWER AIR’s load frame is particularly stiff. A base plate on the machine table allows for the secure and flexible attachment of different testing fixtures. The traverse can be electrically adjusted. Lateral forces on the pneumatic axis are significantly reduced thanks to the addition of a linear guide in the actuator.

The AIR ACT actuator can be attached both under the table or on the traverse so that loads may be applied from above and below the sample.

Servo pneumatic

Tension-Compression

Bending

Torsion

Technical Highlights

Your Advantages

Technical Highlights

- Nominal load up to 10,000 N

- Dynamic load up to 8,000 N

- Test frequency up to 50 Hz (depending on the load range)

Your Advantages

- Universally applicable

- Height adjustable testing area (easy electrical traverse adjustment)

- Ergonomic working height

- Additional linear guide in the actuator to prevent lateral forces on the pneumatic axis

- Easy load application from above and below

Typical components:

- Elastomer elements

- Bicycle and pedelec components

- Mounting suspensions of exhaust systems

- Innovative materials (foamed metals, carbon fiber components)

- Household device components

Industries:

- Automotive

- Materials

- Medical technology

- Household devices

CoPilot Software

Software recommendations:

- FlightReport

Accessories:

- Compressed air service units

- Standard test fixtures

- Customized test fixtures

- Protective casings

- Temperature control

- Environmental simulations

- Measurement instrumentation