Universal pneumatic cylinder unit

AIR ACT

Highlights

- Universally and flexibly applicable

- Integrated force and displacement senors

Uses

- Testing of elastomer elements

- Determination of force and displacement characteristic curves

- Testing of Pedelec components

- Vibration testing up to 50 Hz

AIR ACT's capabilities

AIR ACT is an affordable, servoe pneumatic cylinder unit that can be used for mobile applications. The cylinder unit unites a variety of functions and components in a single casing. All of the valve technology is built into the actuator unit. The cylinder has plug connections for compressed air and electricity. AIR ACT‘s simplified design ensures ease of setup and operation when using pneumatic components in laboratories.

Using innovative test fixtures, bending, torsion, and combined loads can also be applied.

Servo pneumatic

Tension-Compression

Bending

Torsion

Technical Highlights

Your Advantages

Technical Highlights

- Six different actuator sizes between ± 1 kN and ± 10 kN

- Dynamic load from 100 – 8,000 N (depending on actuator size)

- Max. 250 mm stroke (depending on actuator size)

Your Advantages

- Mobile and thus ideal for testing fields

- Low infrastructure requirements (only compressed air and electricity connections)

- Variable signal types

- Variable amplitudes

- Integrated force and displacement sensors

Typical components :

- Elastomer elements

- Bicycle and pedelec components

- Mounting suspensions of exhaust systems

- Innovative materials (foamed metals, carbon fiber components)

- Household device components

Industries:

- Automotive

- Materials

- Medical technology

- Household devices

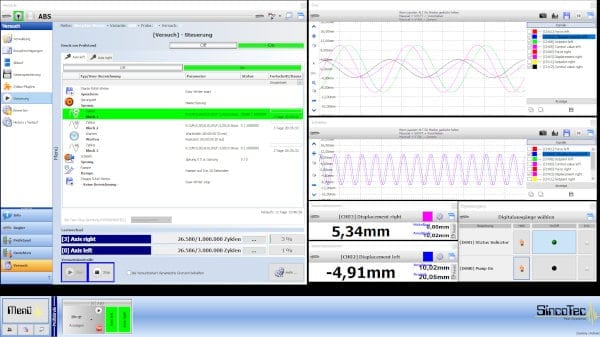

CoPilot Software

Software recommendations:

- FlightReport

Accessories:

- Compressed air service units

- Standard test fixtures

- Customized test fixtures

- Protective casings

- Temperature control

- Environmental simulations

- Measurement instrumentation