Hot-cold and constantly under pressure

New development: flow-through internal pressure pulsation test rig

Internal pressure pulsation test rig

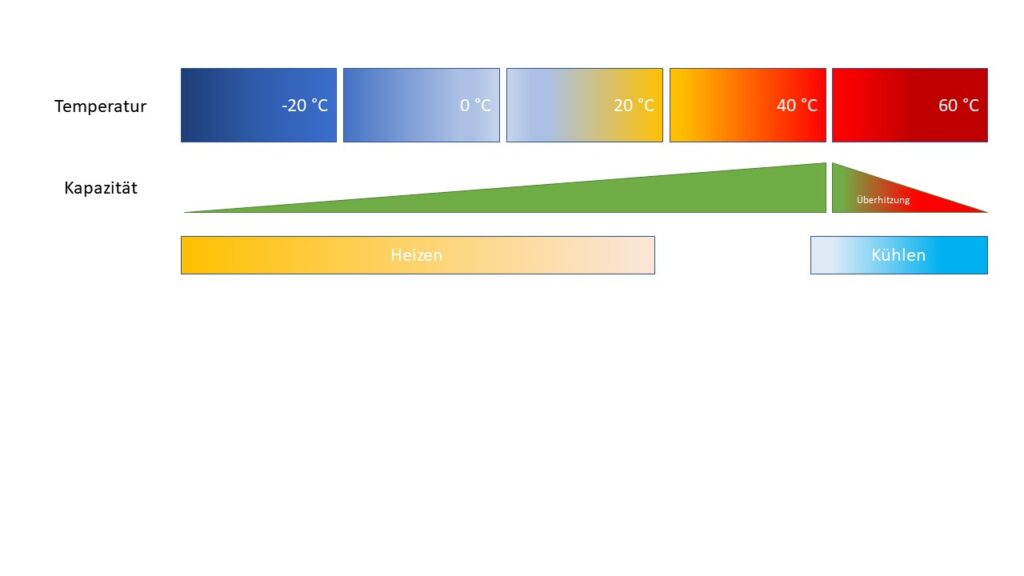

One not immediately visible but nevertheless relevant stress for vehicles with electric drives is the temperature of the individual components of the powertrain. Winter temperatures of -20°C can reduce the range of an e-vehicle by approx. 50%. Consistent monitoring and adjustment of the temperatures of the individual components in the e-drive can significantly improve performance, range and service life. An example of this is the battery. This is cooled in summer and during charging, but must be heated in winter. Thanks to the high efficiency of electric drives, they themselves produce relatively little waste heat. Additional components such as electric auxiliary heaters and heat pumps must therefore be used for heating. In addition, there is a large number of electrically controlled valves, evaporators, fans etc. It is therefore no longer appropriate to speak of a “pure cooling system” for an e-drive vehicle, but rather of a “thermal management system”.

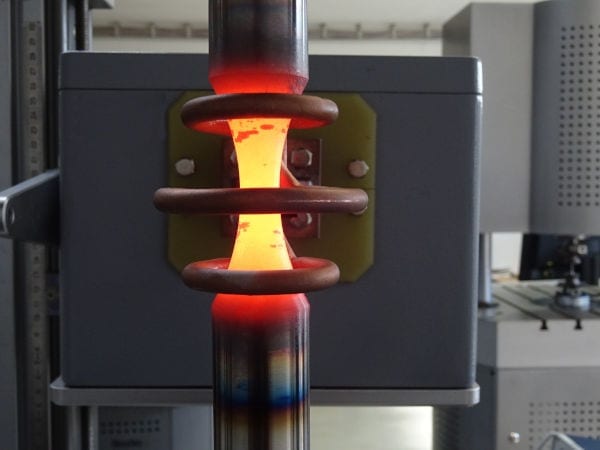

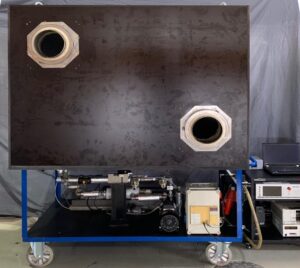

Within this system, there are a large number of components that are subjected to two different temperatures at the same time. On the one hand with the temperature of the coolant, on the other hand with the ambient temperature in which the component is located. Added to this are pressure fluctuations in the cooling system. In order to be able to better simulate this load situation for testing the components, SincoTec Test & Engineering developed a flow-through internal pressure pulsation test rig.

On this test rig, the above-mentioned components, but also other components, can be flowed through with a temperature-controlled coolant and simultaneously subjected to pressure pulsation while these components are at an ambient temperature that differs from the coolant temperature. Ambient temperatures between -40°C and 140°C, media temperatures up to 120°C, pressures between 0 bar and 5 bar (relative) and volume flows up to 50 l/min can be generated.

Internal pressure pulsation test rig

Diagram: Performance of a battery related to temperature

How can we help you?

When it comes to testing your products, components or assemblies for their load capacity, service life and reliability, we have the right solution. Please briefly describe your problem, we will be happy to get back to you in a timely manner!