Strain gauges

Strain gauges measure localized strain on the surface of a component. Using the coefficient of elasticity we can calculate the mechanical tension in that area.

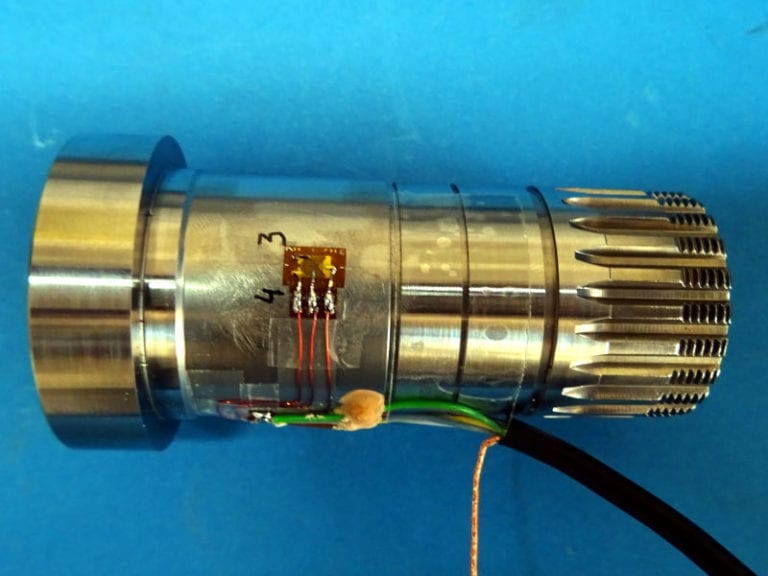

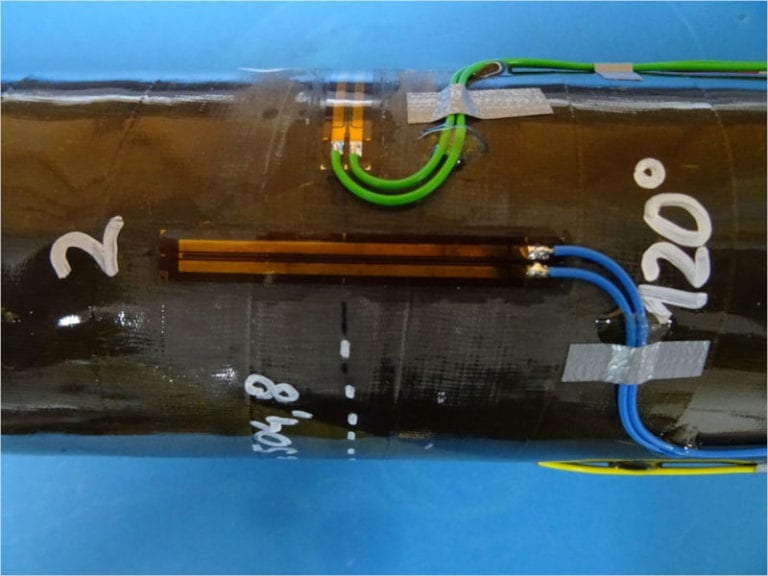

We apply our in-house measurement tools to components of all sizes examining them from all angles.

Our Capabilities

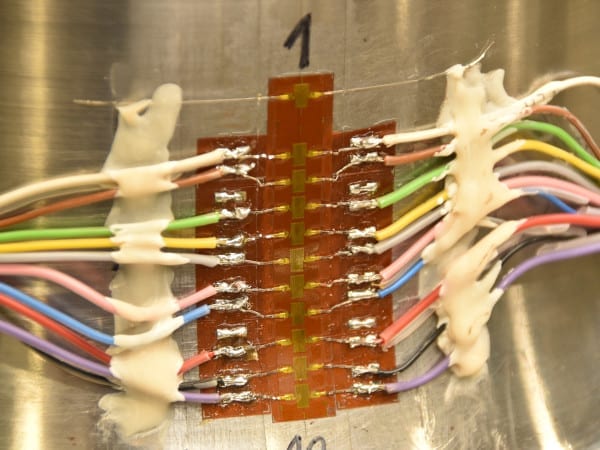

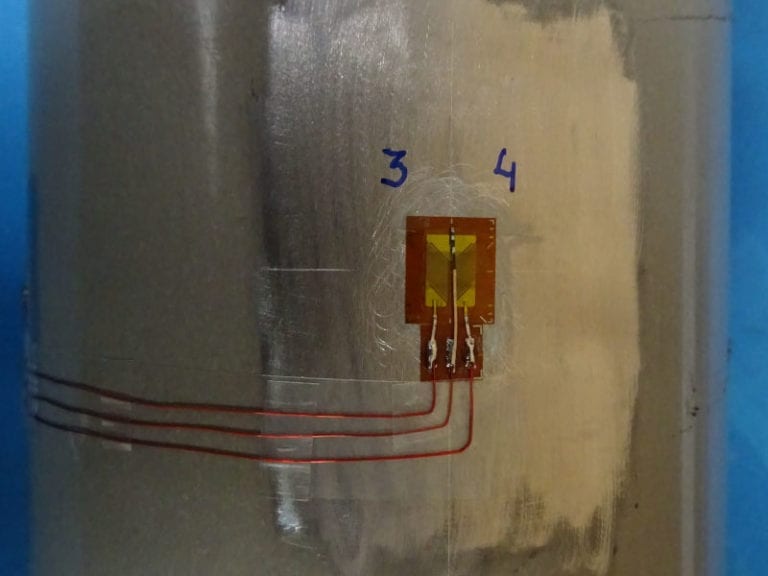

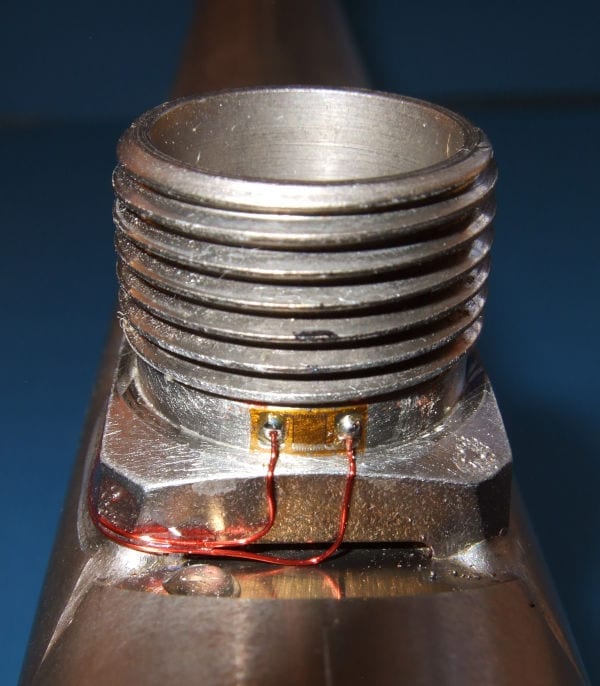

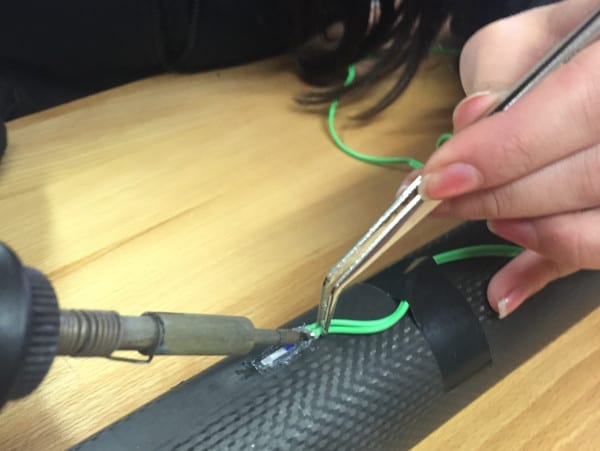

Applying strain gauges

small to large, single axial to multiaxial

Thanks to our experts’ yearslong experience with measurement techniques, SincoTec has the knowledge and capacity to apply and conduct both static and dynamic measurements.

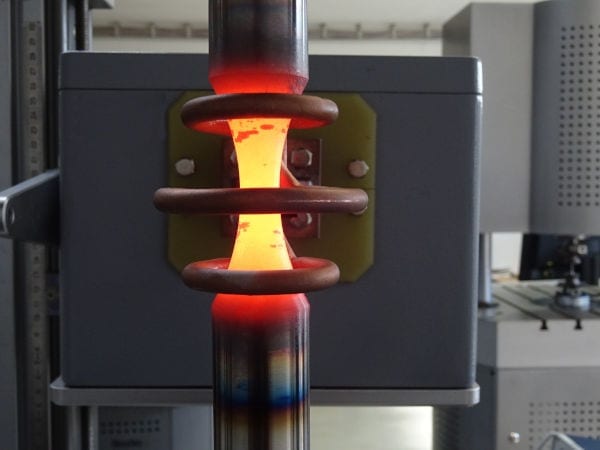

- Strain measurements can be taken using “cold” or “hot” application techniques on all materials using strain gauges

- Measure forces, moments, displacements, angles, accelerations, rotational speeds, temperatures, pressures, etc.

- Calibration and production of all sizes of calibration components

- Development of measurement signals and creation of test programs

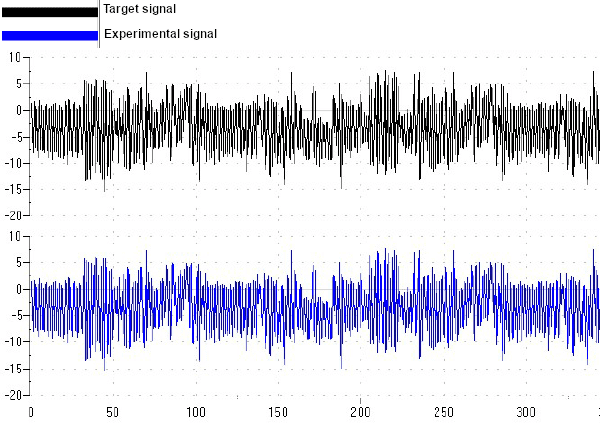

Strain comparisons

Compare results with other tests or with FEM simulations

FEM simulations can be compared with the real strains experienced during testing. The results of different test rigs can also be compared to better understand and classify the results of each test.

Static-Dynamic comparisons

Compare results with previous tests or FEM Simulations

The mass inertia loads of the oscillation system may lead to significant deviations in testing results. Our expert lab technicians are trained to calibrate test rigs to eliminate such deviations and such that testing produces statistically meaningful test results.

Contact us

We have testing solutions for all manner of components, assemblies, and materials to determine their maximum load capacity, lifetime, and reliability. Contact us below with a summary of your testing needs and we will reach out to you as soon as possible.